Quality and Measurement

A COMMITMENT TO QUALITY & A HERITAGE OF RESEARCH & PROCESSING EXCELLENCE

Core to SAT Plating is our Quality FIRST Policy

First Time l On Time l Every Time

F Focused Management Commitment

I Improve Continuously

R Reduce and Identify Risks

S Satisfy Requirements (QMS, Customer and

Regulatory)

T Teamwork – Everyone Plays a Role!

Further, to ensure quality and integrity, SAT employs a variety of measurement and analysis tools.

|

Precise characterization of material surfaces & liquids play a vital role in development of new, better performing products with improved hydrophilic qualities. Measurement of contact angles and surface/interfacial tensions provides a better understanding of the interactions between solids and liquids. These interactions play a key role in understanding adhesion, material wettability, lubricity of solid surfaces as well as the wetting, washability, spreading and absorption of liquids. Contact angle, surface/interfacial tension and surface free energy measurements provide the information needed for the development and modification of solid surfaces using sophisticated surface engineering techniques such as Surface Activation® Processing. |

KSV Cam-100™ |

FischerScope™ X-Ray XDAL |

The FischerScope™ X-Ray XDAL has a large measurement chamber which accommodates specimens with complex geometries. The motor-driven, adjustable Z-axis allows for sample heights of up to 140 mm (5.5"). For large, flat samples such as PC Boards, the housing has openings on the side (C-slot). The measuring system is equipped with a fast, programmable XY-stage, so surfaces can be examined easily in the mapping mode. Also, serial measurements on components, e.g. leadframes, or the measurement of multiple and varied components, can be quickly programmed and executed automatically. |

|

Energy Dispersive X-ray Fluorescence Technology (ED-XRF) provides one of the simplest and most accurate analytical methods for the determination of the chemical composition of many types of materials. It is non-destructive and reliable, requires no, or very little, sample preparation and is suitable for solid, liquid and powdered samples. The Phoenix XRF can be used for a wide range of elements, and provides detection limits at the sub-ppm level; it can also measure concentrations of up to 100% easily and simultaneously. |

Spectro Phoenix XRF™ |

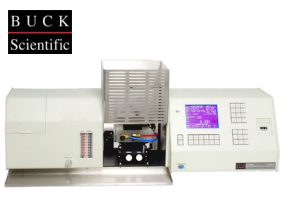

Buck 210VGP Atomic Absorption Spectrophotometer™ |

Analytical Performance: The Buck 210 VGP™ is a high energy, microprocessor controlled single beam atomic absorption spectrophotometer. Solid state electronics and optics provide the basis for superior stability and sensitivity. The mono-chromator and selectable bandwidth give the system maximum flexibility. The short-path dynamic nebulizer/burner configuration is highly efficient. An inert needle delivers sample to the corrosion-proof impact bead. This results in a high nebulization effect for all types of sample matrices. |

SAT Plating can also supply your custom and proprietary plating needs - contact us or call 248.273.0037 to let us know how we can help you!